Applications

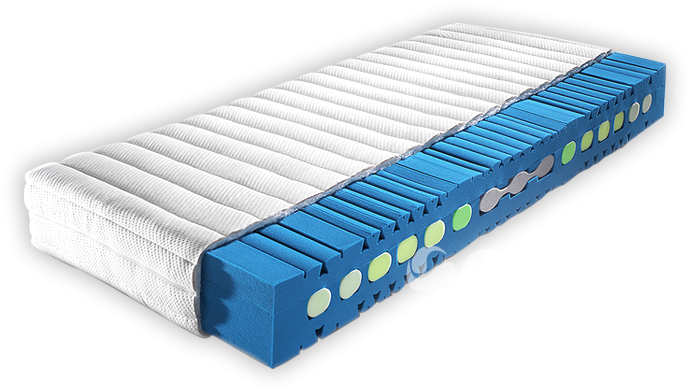

Mattress

The mattress manufacturing process is influenced by a number of important requirements. The adhesives used in mattresses do not only need to bond but also provide long term resistance, comfort and safety for our health. OYTI offers maximum efficiency in the mattress manufacturing process with continuous development of our innovative technology.

OYTI offers the perfect solution for both automatic or manual adhesive application. Tailored to our customers specific application requirements OYTI develops flexible and resistant hot-melt adhesives for the mattress manufacturing process.

Applications

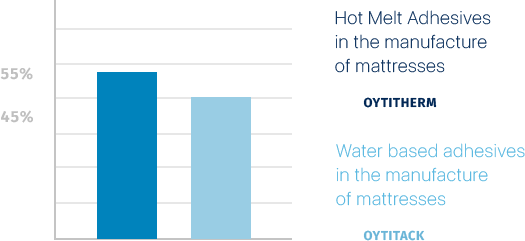

OYTITHERM Hot Melt Adhesives are a reliable solution for the production of mattresses. OYTITHERM adhesives are characterized by flexible, strong and noiseless bond seams even under cold temperature conditions.

Also they are odorless and free of emissions and, therefore, making the workspace safe. Low visibility through textiles and other components of the mattress is guaranteed due to the light and transparent color. Our aim is to provide our customers with adhesives having an outstanding price-performance-ratio.

Applications

OYTITACK Water Based Adhesives are perfectly suited for the manufacture of full foam mattresses. They can be applied by rolls and offer high instant tack.

OYTITACK is available as 1-component and 2-component systems and are completely free of solvents and therefore a environmentally friendly alternative compared to conventional solvent-borne adhesives.